Active Control of Lubricant Temperature in Individual Bearings

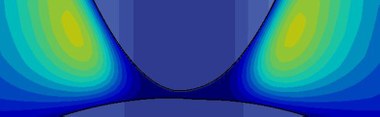

In electro-mechanical drivetrains, different bearings and bearing types occur, all operating under different (variable) loads, speeds and temperatures. Most often, all bearings are connected by a single lubricant circuit, supplying a specific well-selected lubricant with adequate viscosity grade and additive package for the entire system. Although the global temperature of the oil tank may be conditionned, the lubrication conditions (film thickness, cooling rate) at the level of each individual bearing are not necessarily optimal. In this project, by employing CFD-FSI numerical simulation of TEHL in contact regions, it is aimed to investigate the effect of active control of lubricant temperature in individual bearings on close to optimal behavior and, efficiency and lifetime enhancement of a system of bearings.

Contact Mohammadreza Banakermani

- Promotors: Patrick De Baets & Dieter Fauconnier