Hardness testing services

A LECO LV-100-AT automatic hardness tester is available at laboratory Soete to determine the Vickers hardness of the material. Material hardness is denoted as the resistance of material to penetration. This is particularly useful during material selection and inspection, since hardness can be associated with machinability and wear resistance of the material.

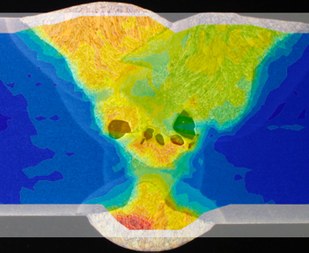

Moreover, hardness is closely linked to other material properties, for instance ultimate tensile strength (UTS). A large number of indents can be applied on the entire sample to get a complete hardness map rather than a local measurement value at one location or on a specific line.

A hardness test is performed by pressing a hard object (indenter) into the test material. The Vickers hardness value is achieved by measuring the area of the mark left by a pyramidal shaped, diamond indenter in accordance with standard ASTM E92 and ASTM E384.

- Indentation force ranging from 0.3 to 30 kgf.

- Number of indents ranging from 1 to more than 1000 indents per sample.

- Hardness mapping of weld, components to evaluate (surface) treatments/coatings/wear resistance…