Surface profile characterization services

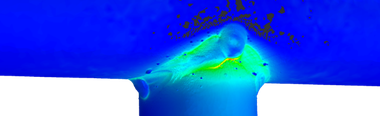

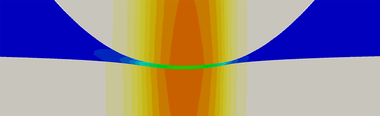

The surface topography of a component includes the profile shape and roughness (microscopical peaks and valleys). The surface structure is typically already created during the manufacturing process and potentially adjusted during service life (e.g. wear).

Since, the structure of the surface topography has a significant impact on several operation characteristics including friction, sealing, heat transfer… , it may be an important part of quality management.

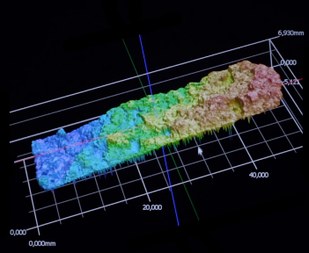

At Laboratory Soete, the surface topography can be measured using contact and non-contact measurement devices. Non-contact devices allow fast 3D-imaging and analysis using light projection. These instruments can be used to replace or in combination other measurement devices such as calipers and profilometers.

- High accuracy measurement of the surface topology, roughness, contour and form of the scanned object

- Structured white light, non-contact scan.

- Wide area up to 225 mm x 157 mm

- 0.01 nm resolution and 0.02 nm repeatability

- Maximum sample heights up to 75 mm

- Maximum sample weight up to 10 kg.