Model-based design for polymeric material applications

The application properties of polymeric materials and specifically fibrous materials are determined by (i) the composition and topology of individual polymer molecules at the molecular scale; (ii) the morphological interactions at the meso-scale defining the polymer microstructure; (iii) and macroscopic features at the macro-scale, hence, final product scale. A true design of these materials requires a fundamental understanding of both the polymer synthesis and the polymer (post)processing steps.

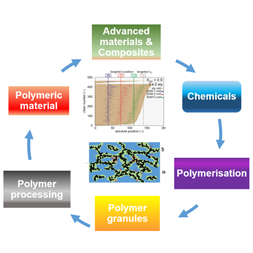

The transition from chemicals to the final application needs to be studied via a modular approach, starting from the basic chemicals and evaluating the full circularity at the final product level (e.g. solar cell, drug delivery device or packaging material). Since phenomena at different scales, ranging from the molecular to the macroscopic scale, are occurring with many parameters influencing the material performance, a multi-scale modelling approach is highly recommended.

Together with the Laboratory for Chemical Technology (LCT), the Centre for Macromolecular Chemistry (CMaC) and several (inter)national academic and industrial partners an advanced multi-scale tool has been developed and already applied for many cases. This tool allows design of well-defined (co)polymers during their synthesis up to industrial scale as well as their mechanical or chemical recycling. Focus is on the control over chain length, composition, topology, and functionality of the individual polymer molecules, benefiting from pioneering algorithms to store and visualize/map detailed molecular information and to properly account for diffusional limitations induced by viscosity changes. At the reactor scale, inhomogeneities due to concentration and temperature gradients are accounted for. Attention is focused both on homogeneous (e.g. bulk) and heterogeneous (e.g. emulsion) polymerizations, taking into account the impact of scale-up on the overall polymer product homogeneity. The software is available in an industrial framework and GUI setting. The tool is also being used in collaboration with the Centre for Textiles Science and Engineering (CTSE), e.g. the molecular design of nanofibrous membranes and artificial turf applications.

Together with CTSE, the Centre for Polymer Materials and Technologies (CPMT) and several (inter)national academic and industrial partners, multi-scale design is also applied for polymer processing, making a differentiation between solution-based (e.g. electrospinning) and melt-based (e.g. extrusion of filaments) methods. The ultimate goal is a powerful fast tool to control the product homogeneity and the application properties by identifying the most suited process parameters (e.g. temperature and pressure profile for extrusion), taking into account economic constraints and variations in the polymer structure and feed composition. This research topic is multidisciplinary and involves the linkage of knowledge on material science, chemical and mechanical engineering, physics and polymer chemistry. The software is again available in an industrial framework.

Further information

Five relevant publications are:

- 3D design of crosslinked and polymer network materials:

- Morphology design for cost-effective piezoresistive sensors

- Model-based sustainable extrusion processes and recycling

- Chemical design and reactive processing

- Multi-dimensional design for high-quality polymer manufacturing

Contact

Prof. dr. ir Dagmar R. D'hooge (Dagmar.Dhooge@UGent.be)