Digital twins for textile materials and processes using a new textile modelling framework

High fidelity textile modelling provides new means of material and process development and optimization. Thanks to highly accurate computer models of textiles, we are able to predict the kinematical and mechanical behavior of yarns and fabrics. The simulations cover material properties, dynamical behavior, microstructure, … and are implemented in commercial finite element software for ease of use.

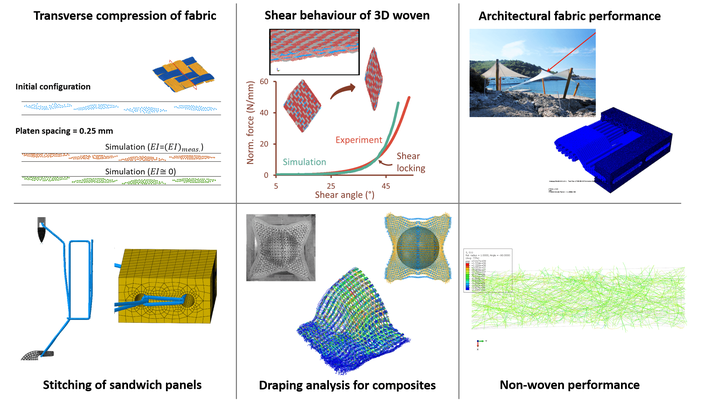

Advanced material simulation is a key technology for engineers in industry. Material and process optimization are key factors that could improve textile production and application, especially with the quest for faster and better production processes as well as higher material performance in technical applications. Modelling of textile materials has long posed problems due to their complexity. We have therefore developed a new simulation method using finite element analysis which has the capability to simulate and predict the microstructure of textiles as well as their mechanical behaviour. The figure and list below give an impression of some applications developed using this method:

- mechanical behaviour of 3D woven glass/PET fabrics in in-plane tension and shear for application in compression moulded composites

- tufting of yarns for manufacturing of sandwich composites

- draping of fabrics for thermoforming/compression moulding of composites

- transverse compression behaviour of fabrics during compaction inside a production mould for composite manufacturing

- mechanical behaviour of coated fabrics for architectural and shelter applications

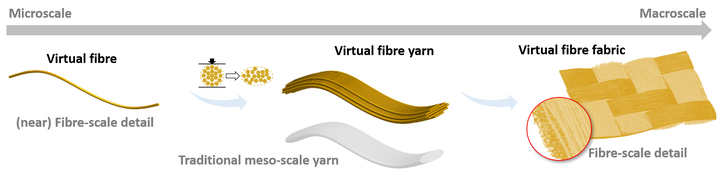

The modelling approach is based on the so-called Virtual Fibre (VF) method (also called Digital Element method). The core idea is to still model fibres explicitly, but not all of them. A yarn or a fabric is represented by a collection of a more limited number of virtual fibres. For example, instead of a 3K yarn with 3000 filaments, 50-60 virtual fibres are modelled that mimic more or less correctly all deformation modes of the real yarn. The modelling framework is physics-based and the yarn and fabric models are calibrated by information from the yarn datasheets and well-known properties of the fabric (number of warp/weft yarns per centimetre, crimp angle, areal weight, etc.).

Further information

- Daelemans, L., Tomme, B., Caglar, B., Michaud, V., Van Stappen, J., Cnudde, V., … Van Paepegem, W. (2021). Kinematic and mechanical response of dry woven fabrics in through-thickness compression : virtual fiber modeling with mesh overlay technique and experimental validation. COMPOSITES SCIENCE AND TECHNOLOGY, 207. https://doi.org/10.1016/j.compscitech.2021.108706

- Dinh, T. D., Rezaei, A., Daelemans, L., Mollaert, M., Van Hemelrijck, D., & Van Paepegem, W. (2017). A hybrid micro-meso-scale unit cell model for homogenization of the nonlinear orthotropic material behavior of coated fabrics used in tensioned membrane structures. COMPOSITE STRUCTURES, 162, 271–279. https://doi.org/10.1016/j.compstruct.2016.12.027

- Daelemans, L., Faes, J., Allaoui, S., Hivet, G., Dierick, M., Van Hoorebeke, L., & Van Paepegem, W. (2016). Finite element simulation of the woven geometry and mechanical behaviour of a 3D woven dry fabric under tensile and shear loading using the digital element method. COMPOSITES SCIENCE AND TECHNOLOGY, 137, 177–187. https://doi.org/10.1016/j.compscitech.2016.11.003

Contact

Prof. dr. ir. Lode Daelemans (Lode.Daelemans@ugent.be)