Comfort of textiles and garments

Balancing comfort and safety in personal protective clothing

To meet protective requirements, comfort in personal protective clothing (PPC) is often sacrificed, impacting both physical and mental well-being. Evaluating comfort is challenging due to its individual and complex nature, influenced by various clothing factors and body-clothing-environment interactions. To address this, effective comfort evaluation protocols are essential for developing lightweight, multifunctional materials for next-generation PPC, ranging from military wear to surgical gowns.

Creating next-generation personal protective clothing (PPC) requires balancing comfort and protection, which is challenging due to the complex, interdependent comfort aspects of thermal, ergonomic, tactile, and psychological factors. Sweat management is especially difficult in bulky, less permeable protective layers, but new materials and wearable systems, like cooling vests, show promise in optimizing this balance. The development of multifunctional, micro and nanoscale functionalized, and smart adaptive textiles offers potential for lightweight clothing with enhanced thermoregulation and protection. Comfort evaluation of PPC combines subjective and objective measurements, along with computer modelling of body-clothing-environment interactions. While subjective assessments are less reliable, combining both methods can offer a more accurate comfort model. One of the challenges during clothing comfort evaluation is the lack of standardization, making comparisons with literature data challenging, and comfort research crucial.

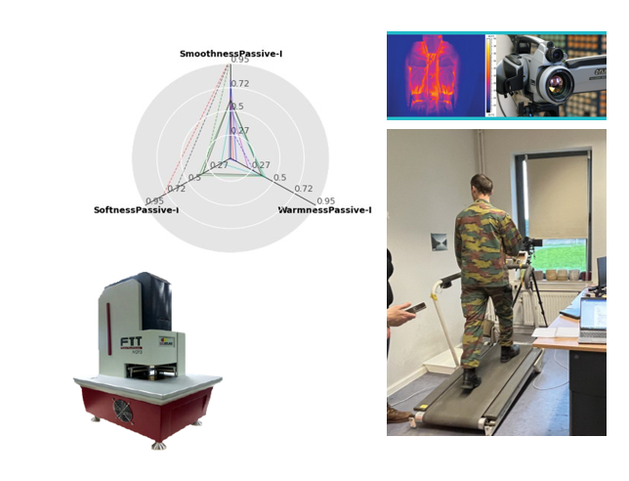

This research focuses on developing a user-centric comfort evaluation protocol, incorporating both objective and subjective tests. Case studies include military clothing and surgical gowns (disposable and reusable). Subjective surveys are used to assess user perception and identify comfort issues, while objective tests, such as water vapor and air permeability, Sweating Guarded Hot Plate, and the Fabric Touch Tester (FTT), are used to evaluate fabric-level comfort. Then, prototyping and human trials with objective and subjective measurements, including temperature and humidity sensors, infrared cameras, and heart rate sensors are used to validate the fabric tests. The summary of these tests together and correlation of the tested parameters should give us interesting insights into the comfort of a person in different settings. Our recent studies using non-invasive comfort evaluation methods concluded that reusable gowns provide significant comfort advantages for hospital use.

Further information

Publications:

- Georgievska, M., Nigusse, A. B., Malengier, B., Tahir, H. R., Harding, C., Derbew TIKU, S., & Van Langenhove, L. (2024). Evaluation of tactile and thermophysiological comfort in reusable surgical gowns compared to disposable gowns. Textiles (Basel), 4(2), 237-255. https://doi.org/10.3390/textiles4020015

- Vasile, S., Georgievska, M., Copot, C., & De Raeve, A. (2023). Comparative analysis of elastic polyester sportswear fabrics with printed graphene patterns. Materials, 16(5), 1502. https://doi.org/10.3390/ma16051502

- Teyeme, Y. W., Malengier, B., Tesfaye, T., Vasile, S.-I., Ciocci, M.-C., & Van Langenhove, L. (2022). Users’ perceptions on comfort level of cycling clothing. In R. Harpa, C. Piroi, & A. Buhu (Eds.), Proceedings of the 7th International Symposium Technical Textiles - Present and Future (pp. 11–16). https://doi.org/10.2478/9788366675735-003

- Teyeme, Y. W., Malengier, B., Tesfaye, T., Ciesielska-Wrobel, I., Haji Musa, A., & Van Langenhove, L. (2021). A review of contemporary techniques for measuring ergonomic wear comfort of protective and sport clothing. AUTEX RESEARCH JOURNAL, 21(1), 32–44. https://doi.org/10.2478/aut-2019-0076

- Haji Musa, A., Malengier, B., Vasile, S., & Van Langenhove, L. (2019). A comprehensive approach for human hand evaluation of split or large set of fabrics. TEXTILE RESEARCH JOURNAL, 89(19–20), 4239–4252. https://doi.org/10.1177/0040517519832834

- Haji Musa, Atiyyah, Benny Malengier, Simona Vasile, and Lieva Van Langenhove. 2018. “Practical Considerations of the FTT Device for Fabric Comfort Evaluation.” JOURNAL FASHION TECHNOLOGY & TEXTILE ENGINEERING, 1–4. https://doi.org/10.4172/2329-9568.S4-003.

Acknowledgements

For this research topic, CTSE collaborates with a.o. FTI labs (Hogeschool Gent), Universiteit Antwerpen and the Defense Laboratories (Vilvoorde, Belgium).

The project titled “Development and Characterization of Smart Textiles in the field of thermophysiological comfort: Optimization of clothing systems and Identification of the Impact of wearing those clothing systems on the operational capability” HFM20-12, is part of the Defense Science and Technology Research Programme (WTOD 2020).

Contact

Prof. dr. ir. Lieva Van Langenhove (Lieva.VanLangenhove@UGent.be)