Sustained load testing on building materials and structural components

Overview

Construction materials are known to exhibit time-dependent deformations. Depending on the structural application it is essential to correctly quantify and predict long-term deformations at controlled load. At low service loads linear visco-elasticity can be assumed and a time-dependent compliance function (deformation per unit stress) can be determined. At higher relative load levels micro-damage is introduced during loading which caused progressively growing stress redistributions until a growing macro-crack ultimately leads to failure (tertiary creep).

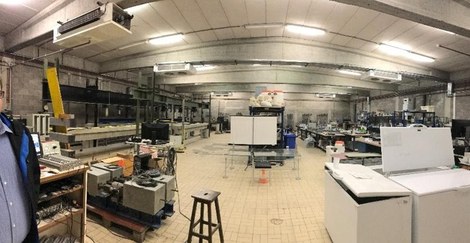

The Magnel-Vandepitte laboratory is well-equipped to perform sustained load tests on standard material specimens as well as structural components at controlled standard conditions.

The equipment includes

- 30 hydraulically controlled load frames for compressive creep (pressure maintained by gas bottle);

- Pressure maintained by pressurized gas bottles;

- Active servo-hydraulic control of load levels for 16+24 independent setups;

- 16 x 600 kN actuators (hollow cylinders);

- 24 x 220 kN actuators (hollow cylinders);

- 6 x 50 kN actuators (tensile jack);

- Manual deformation measurements by DEMEC sensors;

- Automatic data acquisition of selected setup by HBM Quantum dataloggers

Channel sustained load pump

Reinforced concrete beams subject to sustained loads

Sustained load test on post-installed adhesive anchors

Activities

Research activities include

- Long-term creep of carbon friendly concretes;

- Sustained load behaviour of geopolymer concrete;

- Self-healing of concrete creep;

- Creep at elevated temperatures up to 95 degrees Celsius;

- Sustained load behaviour of post-installed adhesive anchor systems;

- Time-to failure behaviour of post-installed adhesive anchor systems;

- Sustained load behaviour of FRP strengthening systems;

- Sustained load behaviour of fibre-reinforced concrete (steel fibres, macro-synthetic fibres);

- Tensile and compressive creep

Contact