Particles

Particles are at the core of many products or production processes, from consumer goods to high tech industrial or niche applications. Examples can be found in Li-ion batteries and catalysts, as well as in phosphors for LED lighting, drugs, additive manufacturing, etc. Our particle coating technologies can be used to functionalize the surface to match the desired properties needed in the intended application. These functionalities include barriers coatings, metallization, flow enhancement, modification of hydrophobicity and many more.

For demonstrative purposes we selected some examples of surface modified particles:

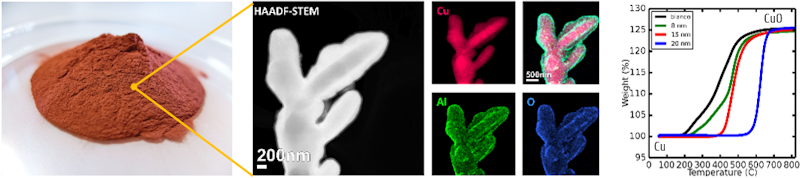

Barrier coatings

The conformal and pin-hole free nature of ALD allows to apply barrier coatings on particles that are sensitive to the environment. In recent years, these barrier coatings were demonstrated at CoCooN on various kinds of powders and particles. The example below shows a conformal ALD Al2O3 coating on copper powder. Whereas the uncoated copper powder readily oxidizes when exposed to air at temperatures above 200°C, the oxidation temperature is increased to 600°C when coated with a thin Al2O3 layer of only 20 nm. Similar barrier coatings have also been applied to phosphor powders, small metal parts and as corrosion protection for copper particles in a wide pH range. For more information, check our publications [1,2,3,4].

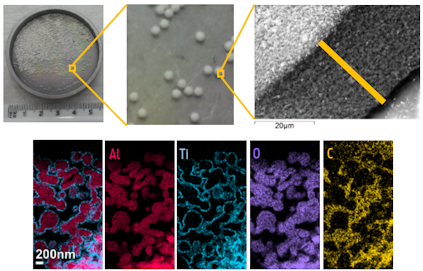

Conformal coating of porous particles

ALD allows coatings to be deposited in porous materials. In this example we applied TiO2 coatings into porous Al2O3 particles. The infiltration depth of the deposited coating inside the particles is tunable. This feature can be useful for instance in catalyst applications.

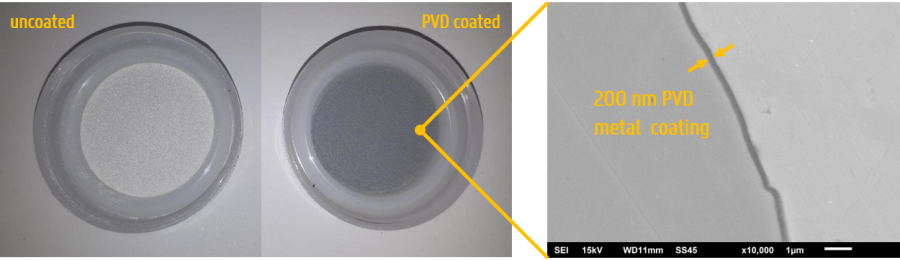

Metallization

Particles can be coated with metal thin films to achieve an electrically conductive surface, or to obtain a metal look. In most cases PVD will be the method of choice.

Turning Teflon hydrophilic using plasma-enhanced ALD

Teflon is known as a hydrophobic material and is extremely difficult to coat. Our plasma-enhanced ALD coatings generate a hydrophilic surface. The coating shows an excellent adhesion and does not degrade over time. We initially started to develop this on Teflon sheets, and later on transferred these processes to Teflon particles. For more information, check our publication [5].

Improving rheology of powders

A major concern in the processing of powders is the flowability (rheology). We developed processes for improving the flow behavior of powders by applying nanometer thin coatings by PE-ALD.

Publications:

- Cremers, Véronique, et al. “Oxidation Barrier of Cu and Fe Powder by Atomic Layer Deposition.” SURFACE & COATINGS TECHNOLOGY 349 (2018): 1032–1041. DOI: 10.1016/j.surfcoat.2018.06.048

- Cremers, Véronique, et al. “Corrosion Protection of Cu by Atomic Layer Deposition.” Journal of Vacuum Science & Technology A 37, 060902 (2019). DOI: 10.1116/1.5116136

- Avci, Nursen, et al. “Microencapsulation of Moisture-Sensitive CaS:Eu2+ Particles with Aluminum Oxide.” JOURNAL OF THE ELECTROCHEMICAL SOCIETY 156, 11 (2009): J333–J337. DOI: 10.1149/1.3211959

- Verstraete, Reinert, et al. “Stabilizing Fluoride Phosphors : Surface Modification by Atomic Layer Deposition.” CHEMISTRY OF MATERIALS, vol. 31, no. 18, 2019, pp. 7192–202. DOI: 10.1021/acs.chemmater.9b01491

- Roy, Amit Kumar, et al. “Plasma-enhanced Atomic Layer Deposition: a Gas-phase Route to Hydrophilic, Glueable Polytetrafluoroethylene.” CHEMICAL COMMUNICATIONS 51, 17 (2015): 3556–3558. DOI: 10.1039/c4cc09474c