Coating of particles

Surface engineering of particles

The uniform and conformal nature of ALD coating technology offers a very precise way of engineering the surface of particles, small parts and porous materials . The COCOON research group has developed ALD and PE-ALD coatings on particles via a patented rotary reactor. In 2014, the group published a review paper on reactor concepts for ALD on agitated particles. Next to ALD and PE-ALD, we developed coating of particles by PVD (magnetron sputtering) as a complementary technique, allowing for a wider process library, including most common metals.

There is a large variety of support materials and structures we are able to coat:

- Powders and particles (nm to mm sized)

- Small parts

- Metals

- Ceramics

- Glass

- Plastics and polymers

These supports can be coated with thin films using ALD, plasma-enhanced ALD (PE-ALD) and PVD.

Our coating chemistries includes:

- Metal oxides (Al2O3, SiO2, TiO2,…)

- Metal nitrides (AlN, TiN, VN,…)

- Metals (Pt, Ru, Ni, Al, Ti,…)

Our capabilities include:

- R&D with broad network for characterization

- Kilogram-scale coating of particles and small parts

- Custom reactor design and development

- Upscaling

Find out about applications that can take advantage of coated particles.

Publications:

Longrie, Delphine, et al.. “Reactor Concepts for Atomic Layer Deposition on Agitated Particles: a Review.” JOURNAL OF VACUUM SCIENCE & TECHNOLOGY A 32, 1 (2014). DOI: 10.1116/1.4851676

Longrie, Delphine, Davy Deduytsche, Johan Haemers, et al. “A Rotary Reactor for Thermal and Plasma-enhanced Atomic Layer Deposition on Powders and Small Objects.” SURFACE & COATINGS TECHNOLOGY 213 (2012): 183–191. DOI: 10.1016/j.surfcoat.2012.10.045

Longrie, Delphine, et al. “Thermal and Plasma-enhanced Atomic Layer Deposition of TiN Using TDMAT and NH3 on Particles Agitated in a Rotary Reactor.” ACS APPLIED MATERIALS & INTERFACES 6.10 (2014): 7316–7324. DOI: 10.1021/am5007222

Cremers, Véronique, et al. “Oxidation Barrier of Cu and Fe Powder by Atomic Layer Deposition.” SURFACE & COATINGS TECHNOLOGY 349 (2018): 1032–1041. DOI: 10.1016/j.surfcoat.2018.06.048

Cremers, Véronique, et al. “Corrosion Protection of Cu by Atomic Layer Deposition.” Journal of Vacuum Science & Technology A 37, 060902 (2019). DOI: 10.1116/1.5116136

Particle coating infrastructure

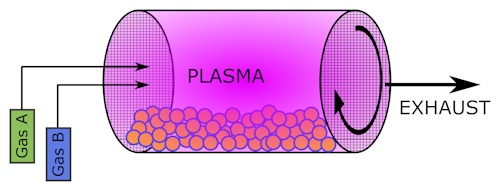

Thermal and plasma-enhanced ALD on particles: The group patented a rotary reactor enabling thermal and plasma-enhanced ALD on particles. The rotating drum enhances the mixing of the gas, plasma and particles, drastically reducing the process time and efficiency. In 2017 the system was scaled up to kilogram capacity. Two other rotary systems have been attached to a glovebox , allowing to work with air-sensitive coatings and substrates, e.g. for Li-ion battery research.

PVD on particles: Complementary to ALD and PE-ALD, we developed a vibrating system for coating particles by PVD (magnetron sputtering), also with kilogram scale capacity. The vibration agitates the particles, allowing for a uniform coating around the particle. Opposite to ALD, only the outer surface is coated. Also this system is coupled to a glovebox.

Other relevant instrumentation at COCOON:

Integrated glovebox infrastructure

Contact

Within the COCOON group, dr. Geert Rampelberg is taking the lead in the PE-ALD and PVD technology for particle coating. He is assisted by dr. Bart Hommez as a business developer at Ghent University.