In situ characterization

In situ characterization during ALD

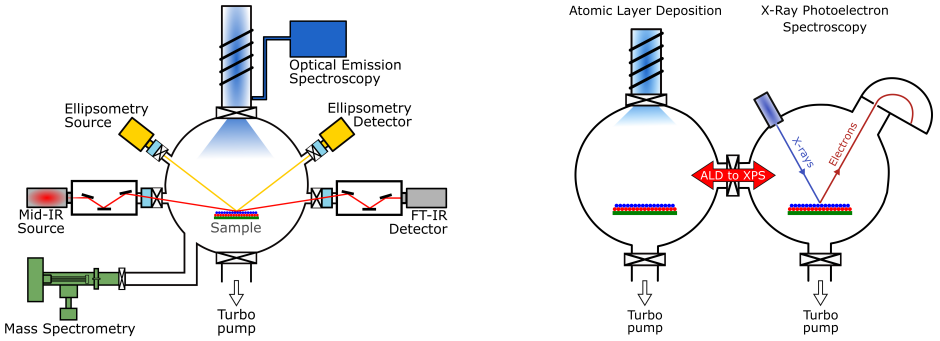

Our home-built ALD reactors are designed to allow for real time monitoring of the ALD growth process. This in situ capability enables rapid evaluation of film growth and detailed studies of reaction mechanisms. The following properties can be monitored during ALD using the in situ techniques that are currently available in the lab:

- The layer thickness, roughness and optical properties by in situ spectroscopic ellipsometry (SE) [1]

- The formed gaseous reaction products by in situ quadrupole mass spectroscopy (MS) [2,3]

- The plasma during PE-ALD by in situ optical emission spectroscopy (OES) [3]

- The chemistry of the surface groups by in situ Fourier transform infrared spectroscopy (FTIR) [4]

- The surface chemistry by in vacuo X-ray photoelectron spectroscopy (XPS) [5]

Next to these lab based in situ techniques, the CoCooN research group has pioneered the use of synchrotron-based X-ray techniques for in situ characterization during ALD.

Publications:

- Dobbelaere, Thomas, et al. “Plasma-enhanced Atomic Layer Deposition of Iron Phosphate as a Positive Electrode for 3D Lithium-ion Microbatteries.” CHEMISTRY OF MATERIALS 28, 10 (2016): 3435–3445. DOI: 10.1021/acs.chemmater.6b00853

- Werbrouck, Andreas, et al. “Time-Resolved in-Situ Mass Spectrometry for Monitoring and Identifying Reaction Products in ALD Processes.” EuroCVD 22 - Baltic ALD 16, Conference Abstracts, 2019. Full text

- Longrie, Delphine, et al. “A Rotary Reactor for Thermal and Plasma-enhanced Atomic Layer Deposition on Powders and Small Objects.” SURFACE & COATINGS TECHNOLOGY 213 (2012): 183–191. DOI: 10.1016/j.surfcoat.2012.10.045

- Van Daele, Michiel, et al. “Surface Species During ALD of Platinum Observed with in Situ Reflection IR Spectroscopy.” PHYSICAL CHEMISTRY CHEMICAL PHYSICS 20, 39 (2018): 25343–25356. DOI: 10.1039/c8cp03585g

- Minjauw, Matthias, et al. “Nucleation Enhancement and Area-Selective Atomic Layer Deposition of Ruthenium Using RuO4 and H2 Gas.” CHEMISTRY OF MATERIALS, vol. 31, no. 5, 2019, pp. 1491–99. DOI: 10.1021/acs.chemmater.8b03852

In situ characterization during thermal processing

The traditional ex situ method to study the effect of e.g. annealing on materials properties consists of the 'cook-and-look' approach: one prepares e.g. 10 identical samples, each of which are subjected to a certain thermal treatment. After cooling down, a certain property (e.g. phase composition) of each of the samples is measured ex situ, and one then tries to analyze the kinetics of the reaction under study on the basis of this limited set of measurements. This ex situ approach is labor intensive and produces relatively few results.

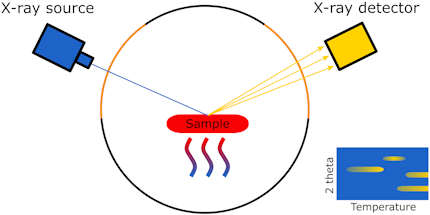

Alternatively, one can use in situ measurements to observe the evolution of the sample in real time, i.e. while the process is taking place. The CoCooN group at UGent has a core background in designing and using dedicated systems for in-situ characterization during annealing of thin films. Note that the annealing ambient can be selected from a range of gasses such as helium, argon, nitrogen, oxygen, hydrogen and others. With these setups, we can monitor different physical characteristics in function of temperature:

- Crystallography by means of in situ X-ray diffraction (XRD). This technique has been upgraded with an automatic sample changer for high-throughput purposes. It is also applicable to powders.

- Surface roughness and agglomeration by in situ laser light scattering and spectroscopic ellipsometry

- Sheet resistance by in situ four-point probe measurement

- Stresses in films by in situ wafer curvature measurements

- Layer thickness, optical properties and porosity by in situ spectroscopic ellipsometry

Each individual use of these techniques learns us a lot about the physical system under investigation. When combining several different tools, CoCooN lab is an excellent research place for this kind of research!

Publications:

Deduytsche, Davy, et al. “High-temperature Degradation of NiSi Films: Agglomeration Versus NiSi2 Nucleation.” JOURNAL OF APPLIED PHYSICS 98, 3 (2005). DOI: 10.1063/1.2005380

Rampelberg, Geert et al. “In Situ X-ray Diffraction Study of the Controlled Oxidation and Reduction in the V-O System for the Synthesis of VO2 and V2O3 Thin Films.” JOURNAL OF MATERIALS CHEMISTRY C 3, 43 (2015): 11357–11365. DOI: 10.1039/c5tc02553b

Galvita, Vladimir, et al. “Structural and Kinetic Study of the Reduction of CuO-CeO2/Al2O3 by Time-resolved X-ray Diffraction.” CATALYSIS LETTERS 142.8 (2012): 959–968. DOI: 10.1007/s10562-012-0859-4